|

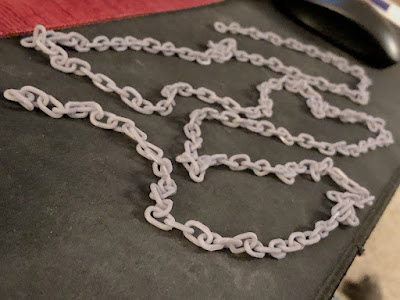

| 3D Printed chain length |

This was a 3D printing test for an articulated chain layout. It used gray UV cure, water washable print resin. The design for the chain is continuous, and already linked together. The pieces are close enough in proximity to get lightly fused, so as to be easily snapped apart after curing. This single level was printed in about 20 minutes. At this particular scale, 1 level made a chain about 60 inches in length. If increased to multiple levels, it could allow a block of chain potentially 100ft long.

|

| Chain strands model layout |

|

| Single Level |

|

| Unsnapping fused elements |

|

| Final released links |

The links were heavily fused in this test, likely from overexposure. Printing did come apart without breaking. A few links cracked, and there were chips and pits where the thick material was snapped apart. The links are strong enough to work with for miniature models.

This trial used no supports and although convenient, there were side effects. The base points fused well, but the base layer thickness created difficulty unsnapping the links. Also the reflectivity of the steel base-plate creates distortion in material exposure of early features.

Overall a successful test with some further tweaks needed to improve the outcome. We will continue with variations of this experiment, maybe with slight layout adjustment and supports. Also find out how it scales.

Next Steps:

- Adjust exposure time and print settings

- Support the base layer

- Test other possible layouts

- Determine how small it can scale

- Attempt to add several more levels